Properties

Assets You Can Trust

THIOCRETE® is a 100 % cement‑free concrete in which water and cement are replaced by sulfur as a binder. This advanced material not only meets the strictest functional and regulatory standards, but it also offers:

- Outstanding mechanical strength

- Superior chemical resistance

- Long-term performance, thanks to its intrinsic hydrophobicity which prevents aging

Read on to discover the exceptional properties of this innovative material.

A Technological Breakthrough

High Mechanical Strength

THIOCRETE® ranks among the highest strength classes on the market and exhibits excellent fatigue resistance.

THIOTRACK®

SNCF dynamic loading tests (10–126 kN at 5 Hz over 3.1 million cycles) showed no loss in mechanical performance.

| Research center: | SNCF Centre d’Essais PSIGT, SaintOuen |

| Standards: | EN 132301/2, EN 134812, CT IGEV 003 E |

THIOTUBE®

Our DN250 mm, class 240 sewer pipes withstand crest pressures of 60 kN/m, confirming their robustness.

Exceptional Acid Resistance

Regardless of extreme tests—both in labs and real-world settings over 7 years—THIOCRETE® maintains integrity in acidic environments ranging from pH 0 to 12.

In the TAP test (UGent – Labo Magnel, Prof. Dr. N. De Belie), rotating disks were cyclically exposed to lactic, acetic, and sulfuric acids for 6 weeks under mechanical brushing.

No deterioration was observed, underscoring sulfur concrete’s resilience.

| Research center: | Labo Magnel, UGent |

| Test standard: | TAP test (Prof. Dr. Ir. Nele De Belie) |

Thermal Durability

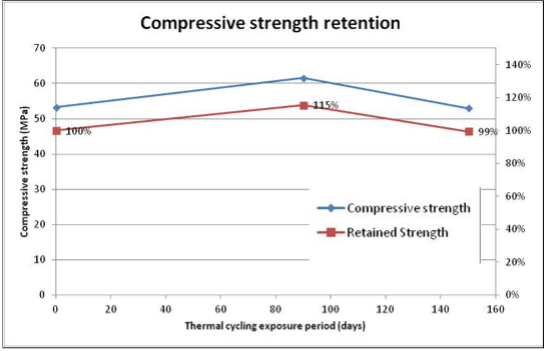

Tested from 20 °C to 80 °C—covering compressive/tensile strength, dynamic modulus, and one-year creep—THIOCRETE® retains 95 % of its initial strength under prolonged or cyclical exposure up to 80 °C.

| Research center: | SGS Intron (NL) |

| Standards: | NENEN 123903, 6; NENEN 199211 |

A sequence of significant temperature fluctuations does not lead to an accelerated decline in material performance. This is demonstrated by tests carried out over 150-day cycles at temperatures ranging from -20°C to 60°C, in combination with relatively high humidity levels.

Vibration Resistance

THIOCRETE® is a high-strength concrete that is highly resistant to alternating loads (‘fatigue’). This is proven by extensive tests with alternating loads on THIOTRACK® sleepers.

The SNCF test centre carried out dynamic tests to check the sulphur concrete’s resistance to changing stresses between 10 and 126 kN, at 5 Hz and for 3,106 cycles. No deterioration of the mechanical properties was observed at the end of these tests.

| Research center: | SNCF Centre d’Expertise et d’Essais PSIGT.LVE.T4 de Saint-Ouen (Fr) |

| Standard: | EN 13230-1/2, EN 13481-2 and CT IGEV 003 E |

Hydrophobic and Water-Repellent

With water absorption between 0.2 %–0.5 %, THIOCRETE® is vastly superior to standard concrete (3 %–8 %). This low permeability protects against liquid ingress and degradation during freeze-thaw cycles.

| Research center: | SGS Intron (NL) |

| Standards: | NEN EN 123502:2000, NEN EN 1339 |

Fire Resistance

Certified under fire class A2 by fire-safety specialists WRF in Ghent, THIOCRETE® remains practically non-combustible. It only melts superficially under high heat—preventing flame propagation.

Proven impermeability to water

Thanks to its dense microstructure and hydrophobic nature, THIOCRETE® achieves impermeability at 1 bar of water pressure in just 1 cm thickness.

Internal tests confirm THIOTUBE® pipes and joints are fully watertight at 1 bar, maintaining full material properties

Outstanding Abrasion Resistance

In the “Darmstadt tilting flume” test (DIN EN 2953), halfpipe samples were rock-cycled up to 400,000 times with gravel. THIOCRETE® performed on par with standard concrete: an initial surface wear followed by aggregate-protected endurance, comparable or better than vitrified clay.

| Test center: | in-house |

| Standard: | Darmstad test (DIN EN 2953) |