THIOTRACK

Tracks to the Future with 100% Circular Sleepers

THIOTRACK® sulphur concrete sleepers offer railway infrastructure managers greater peace of mind. They meet all functional and technical requirements defined in European standards and technical specifications and go much further when it comes to environmental impact.

Unlike traditional cement-based solutions, THIOTRACK® sleepers combine high performance with exceptionally low carbon emissions, delivering future-proof infrastructure aligned with circular economy principles.

A New Standard in Sustainable Rail Infrastructure

As the railway industry works to reduce CO₂ emissions while maintaining cost-efficiency and durability, concrete sleepers remain a key focus. Traditional cement-based sleepers are among the largest carbon contributors in rail infrastructure.

That’s why THIOTRACK® has been developed using THIOCRETE®, a cutting-edge sulphur concrete that:

- Eliminates the need for cement

- Hardens through physical phase change, not chemical hydration

- Is 100% recyclable – no loss in performance, even after a full service life

By reheating and re-molding, old sleepers are reborn as new ones, reducing lifecycle CO₂ emissions by up to 90% compared to conventional solutions.

Performance That Meets and Exceeds Industry Demands

THIOTRACK® sleepers are not just sustainable—they are engineered to perform in the most demanding rail environments:

- Compressive strength consistently between 60 and 80 MPa

- Exceed EN 13230-1:2016 (C45/55), meeting C50/60 requirements set by:

- SNCF (France)

- Infrabel (Belgium)

- ProRail (Netherlands)

- Deutsche Bahn (Germany)

Models like the M41 and M450 are designed for high-speed, regional, and freight traffic, with proven resistance to high axle loads and extreme conditions.

Field-Proven Durability, Worldwide

THIOTRACK® sleepers have been successfully deployed across multiple countries, including Belgium, France, the Netherlands, and Australia.

Case in Point:

M41 sleepers installed more than 11 years ago in Belgium’s coastal region remain structurally sound—despite harsh weather and intense traffic—proving their long-term reliability.

Discover our numerous rail solutions

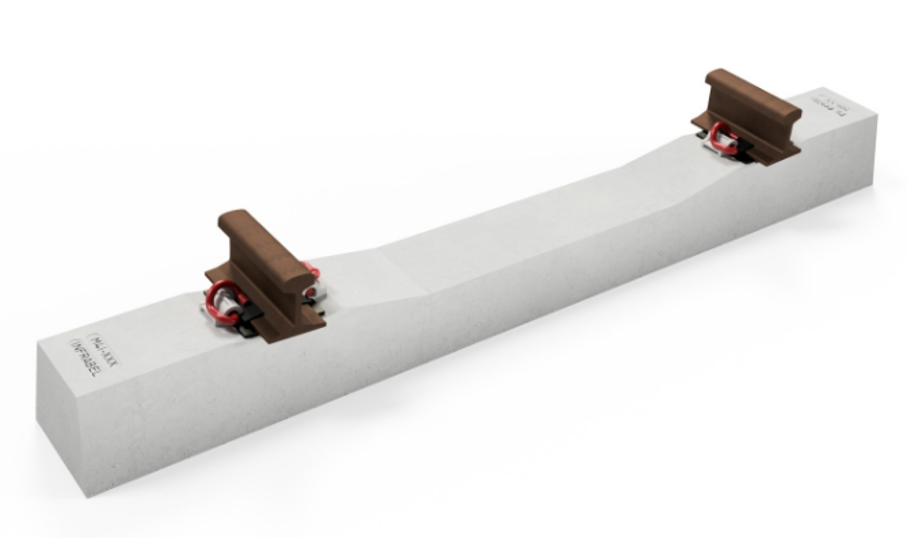

M41 Sleeper

The M41 is the prestressed monobloc sleeper produced from our innovative circular sulphur concrete ‘THIOCRETE®’ and this conforming European standards EN13230- 1 and 2 and the technical specification L23 of the Belgian railway company Infrabel.

| M41 Sleeper | |

| Max axle load | 22,5 tons |

| Dynamic load per wheel | 17 tons |

| Vmax | 350km/hour |

| Fixation system | E-clips system |

| Weight | 310kg |

| Rail Gauge | 1435mm |

| Inclination | 1/20 |

| Rail | 60E1 (UIC60) / 50E2 (50EB-T) |

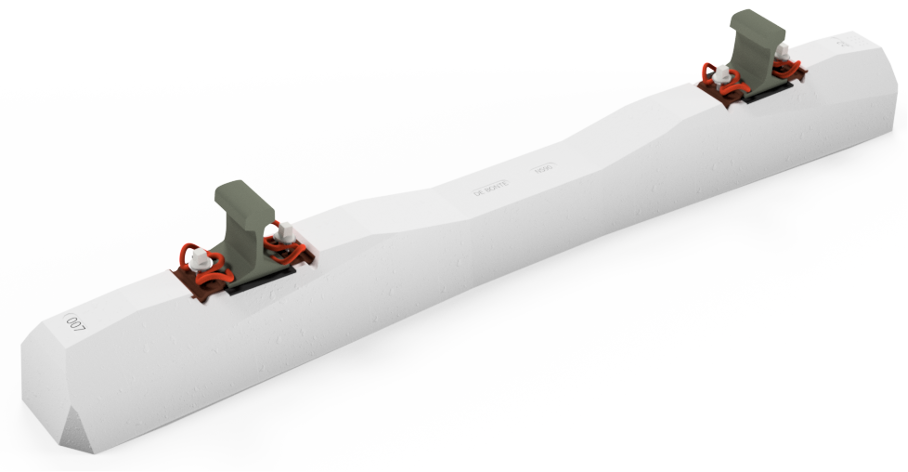

NS90

The NS90 is the pre-stressed monobloc sleeper made of cicular sulphur concrete concrete in accordance with the European standard EN13230-1 and 2 and the technical specification SPC00021 of the Dutch railway company Prorail. The sleeper can be used for both the conventional and high-speed railnet.

| NS90 | |

| Max axle load | 22,5 tons at a speed of 200km/hour 25 tons at a speed of 120km/hour |

| Fixation system | W14 |

| Weight | 280 kg |

| Rail Gauge | 1435mm |

| Inclination | 1/40 |

| Rail | 46E3, 54E1/E5 en 60E1/E2 |

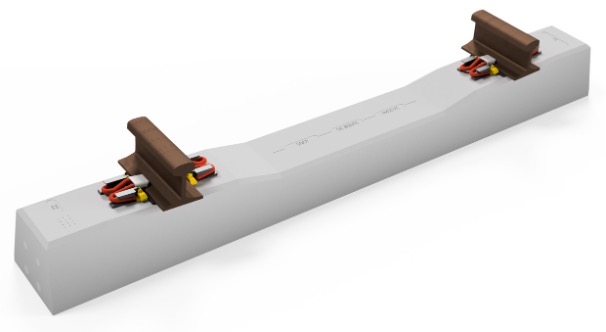

M450

The M450 is a pre-stressed monobloc sleeper made of circular sulphur concrete, designed in accordance with the European standard EN 13230-1 and 2, as well as the technical specification IG04026 of the French railway network. Engineered for both conventional and high-speed rail applications, it is intended for use on the SNCF Réseau network.

| M450 | |

| Variant | PI or NV |

| Max axle load | 22,5 tons at a speed of 250km/h 18 tons at a speed of 320km/h |

| Fixation system | Fastclip or Railtech nabla system |

| Weight | 300 kg |

| Rail Gauge | 1435mm |

| Inclination | 1/20 |

| Rails | 46E2, 55E1, 50E6 and 60E1 |

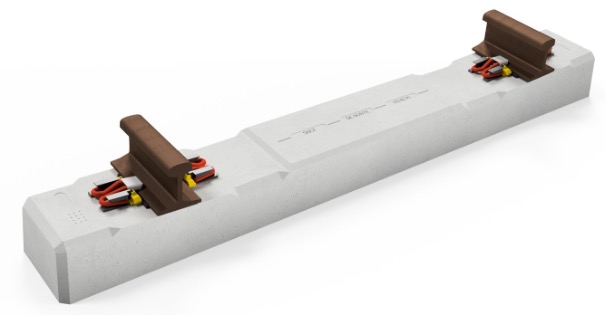

M240

The M240 is a pre-stressed monobloc sleeper made of circular sulphur concrete, designed in accordance with the European standard EN 13230-1 and 2, as well as the technical specification IG04026 of the French railway network. Engineered for conventional rail applications, it is intended for use on the SNCF Réseau network.

| M240 | |

| Variant | PI or NV |

| Max axle load | 22,5 tons |

| Fixation system | Fastclip or Nabla system |

| Weight | 295 kg |

| Rail Gauge | 1435mm |

| Inclination | 1/20 |

| Rails | 46E2, 55E1, 50E6 and 60E1 |

PS94

The PS94 is the pre-stressed monobloc sleeper made of circular sulphur concrete in accordance with European standard EN13230-1 and 2 and technical specification WTWiOnumber ILK3a-5187/01/05 of the Polish railway company PKP.

The sleeper can be used for both the conventional and high-speed railway network.

B70

The B70 is a pre-stressed monobloc sleeper made of circular sulphur concrete, designed in accordance with the European standard EN 13230-1 and 2. Engineered for both conventional and high-speed rail applications, it is intended for use on the Deutsche Bhan network.

| B70 | |

| Max axle load | 22,5 tons at a speed of 230km/h |

| Fixation system | W14 system |

| Weight | 300 kg |

| Rail Gauge | 1435mm |

| Inclination | 1/40 |

| Rails | 60E1, 54E3 en 49E1 |

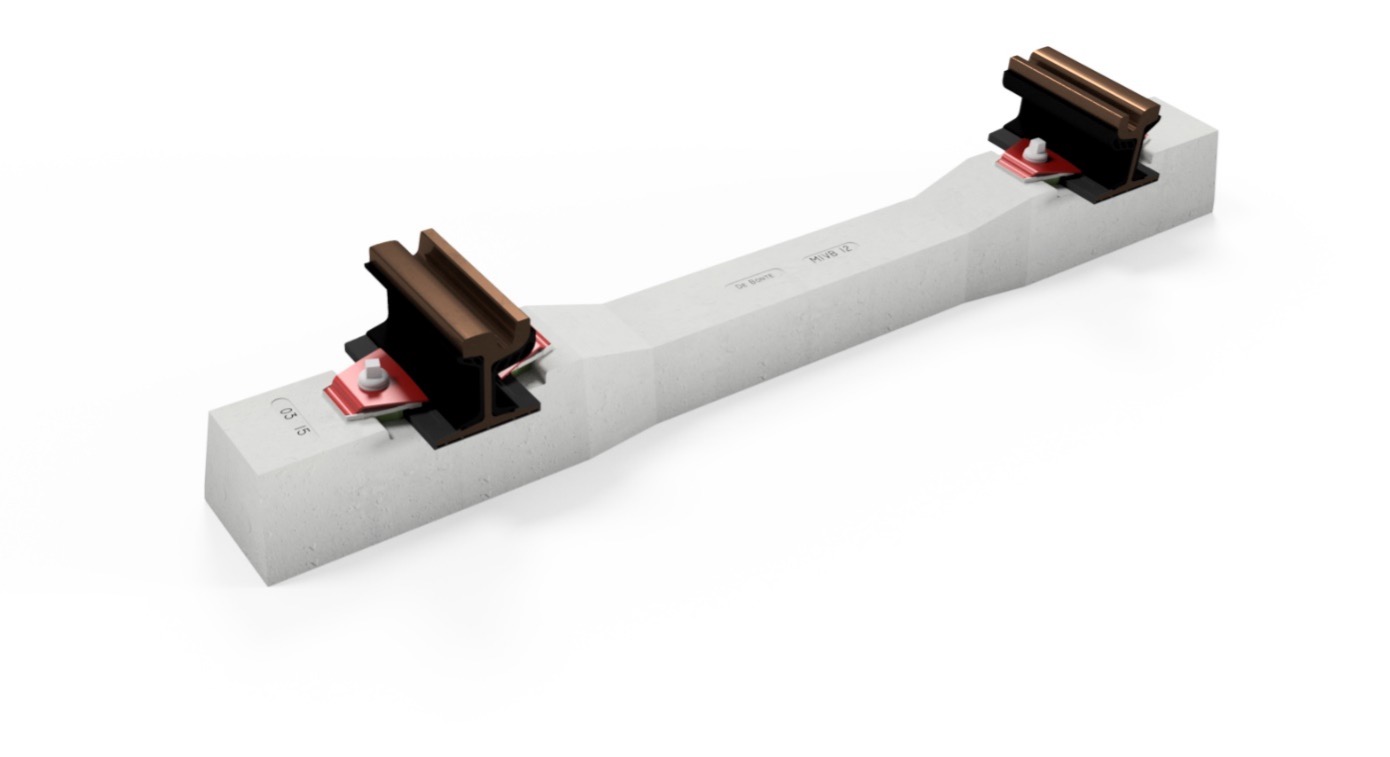

Light Rail

The Light Rail Sleeper is the pre-stressed monobloc tram sleeper made of circular sulphur concrete in accordance with European standards EN13230- 1 and 2.

The sleeper can be used for the Light Rail network such as (speed)tram and (pre)metro.

| Light Rail | |

| Max axle load | 12,5 tons at a speed of 80km/h |

| Fixation system | Pandrol E-clips system or Nabla |

| Weight | 155kg |

| Rail Gauge | 1000mm |

| Inclination | – |

| Rails | 62R1 / 50E2 |